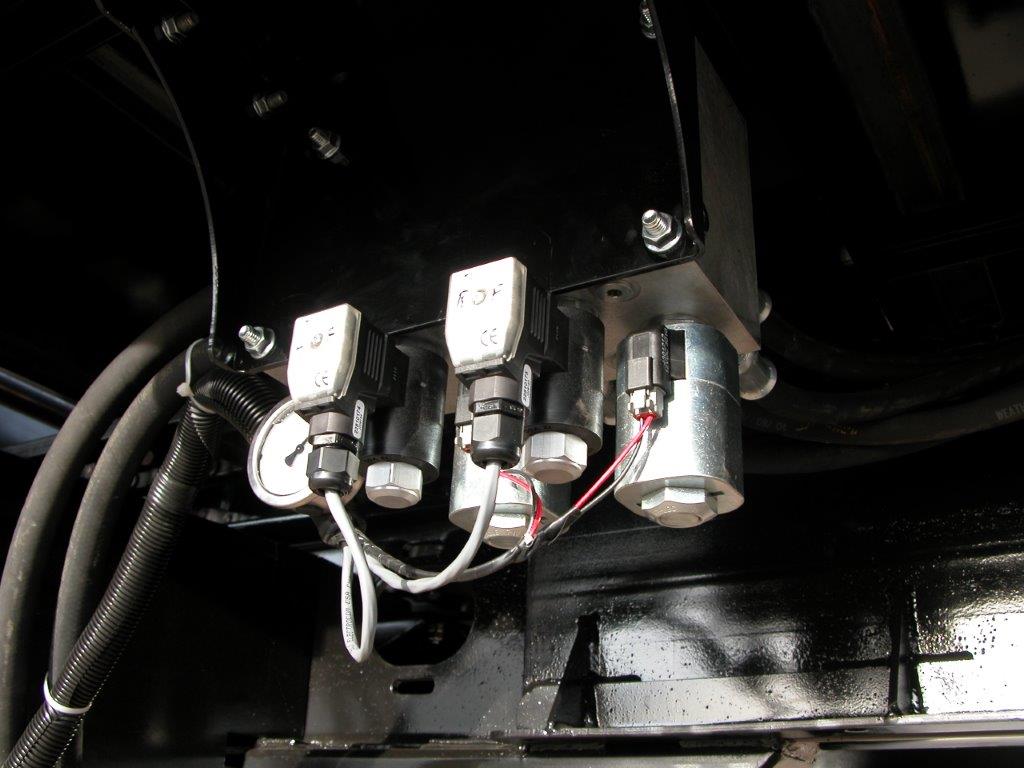

Remote Independent Controls

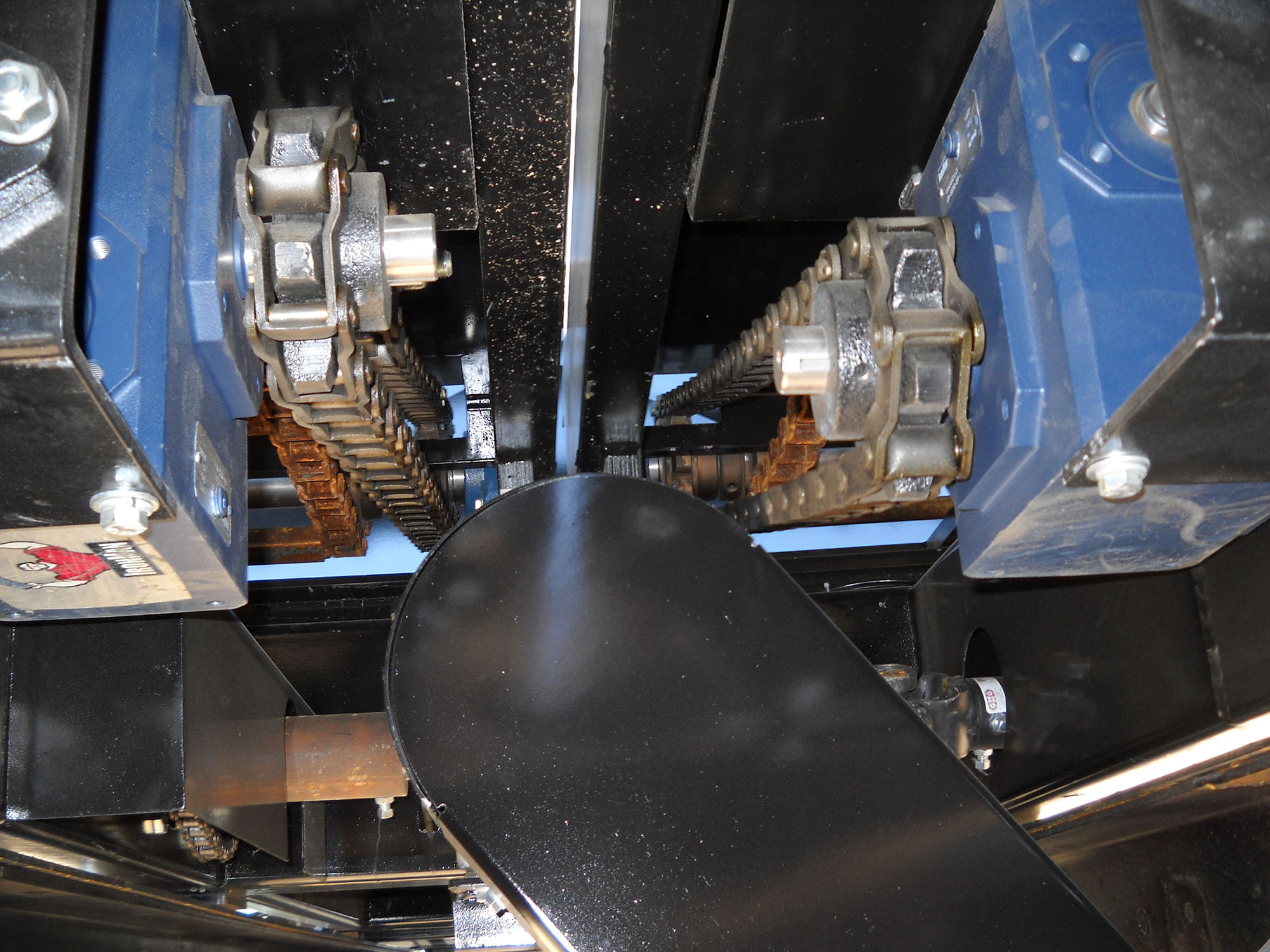

Patented Independent Floor Chains

The EZ Ration Processor has two independently controlled floor chains. The newly patented method allows the producer to adjust the speed of each floor chain individually. The producer can now process two different feeds/hays at the same time but at different rates. The operator can now create a mix of any desired ratio with the feed/hay source on the left and the feed/hay source on the right. The operator can also change the mix on the go according to the nutritional needs of the livestock. Allowing the producer to be as efficient as possible without sacrificing production or time.

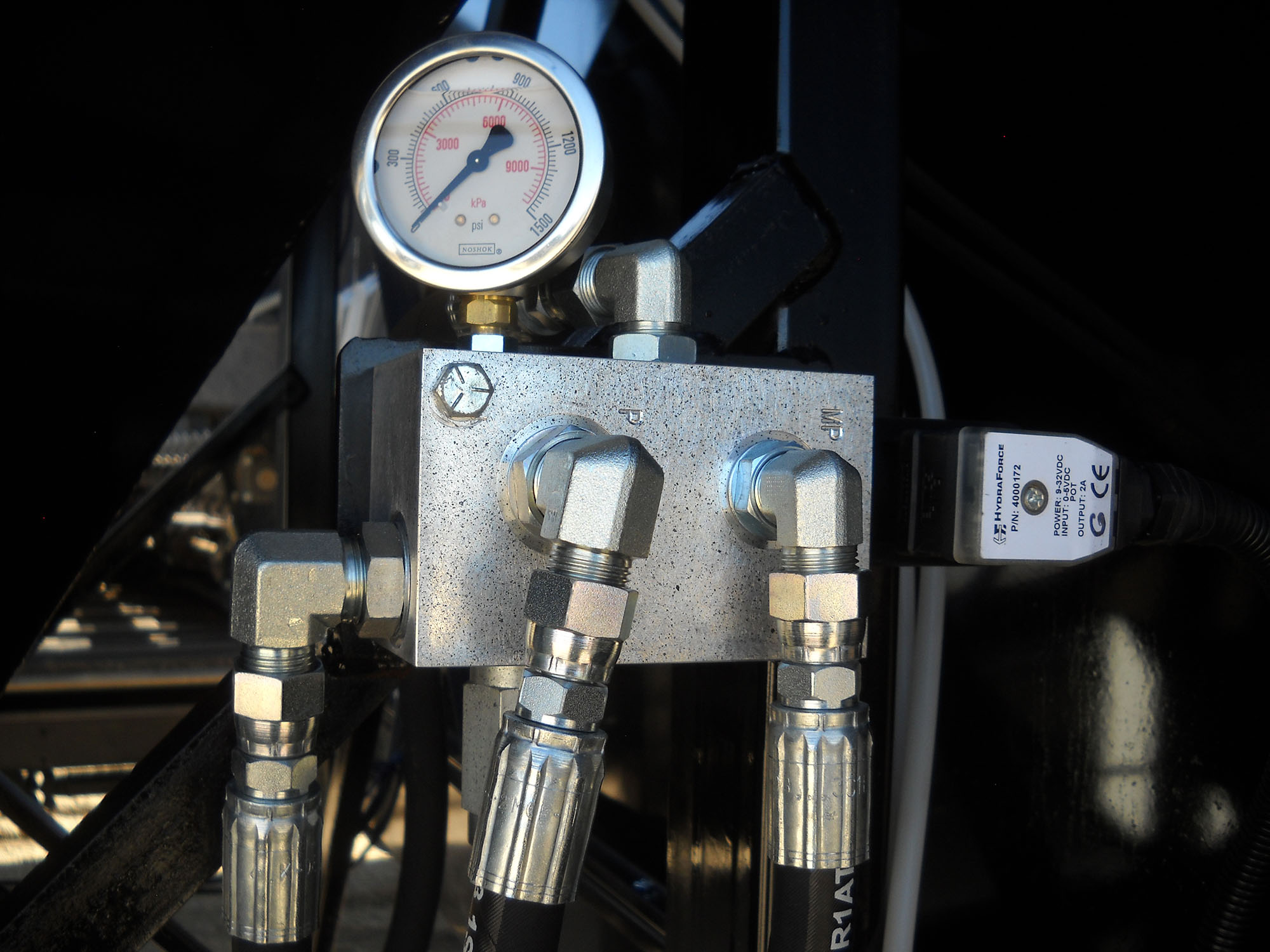

Hydraulic floor controls manifold

The specially designed hydraulic system allows the producer to control and very the speed of each floor chain independently with the in-cab control box. This patented ability provides means for the producer to create any desired blend of the hay or feed source on the left floor chain with the hay or feed source on the right floor chain – plus change it on the go meet the different nutritional requirements of different classes of livestock – such as yearling heifers, first calf heifers, second calf heifers, running aged cows, bulls, etc….

New Knife Configuration

We use sickle sections for cutting knives which allows for easy replacement. We recommend that each feeding season is started with a fresh set of knives/sickle sections – they can be flipped once so one set can be used for two feeding seasons. In heavy use they should be replaced or flipped sooner.

Optional Grain Attachment

With the optional grain attachment the producer can also add grain to the ration in varying amount –This is especially helpful in growing lot or weaning situation — allowing the producer to create a growing ration for weaned calves or replacement heifers – then reduce the amount of grain per head or even turn it off for the cows in the next pasture depending on their current nutritional needs

Grain Attachment control manifold

The speed of the auger can be varied to change the amount of grain or pellets dispensed. This allows the producer to meet different classes of livestock varying nutritional requirements and of course it can be completely shut off if grain or pellets are not needed for that pen or pasture.

Independent Scale System

Independent floor chain drive system

The Patented ability to drive and control each floor chain independently

Shown in the picture is the separate and independently controlled floor chain drive systems. Not shown in the picture are the hydraulic motors that power each gear box. This independent floor chain drive system is simple in concept but dramatic in results. It gives the producer the ability to create a cost effective blend of roughage and it also allows the producer to change that blend to meet different classes of livestock’s nutritional needs –on the go

Options In Economics & Nutrition

The EZ Ration Processor offers the producer options in economics and nutrition that nothing else on the market today can match. With it’s patented ability to create a mix at the same time it is delivering it to the livestock. And the ability to change the mix from pen to pen or pasture to pasture, according to the nutritional needs of the livestock, the producer can be as efficient as possible with out sacrificing production or time.

***** ONE MAN ***** ONE MACHINE ***** ONE OPERATION

Feed Cost Savings

The EZ Ration Processor was designed to process and blend a total ration. Processing the hay alone can reduce the total amount required by 20% to 30%. The EZ Ration Processors’ patented ability to blend high quality roughage with lower quality cheaper roughage can save an additional 30% to 40%. The feed cost savings in some cases can easily exceed 50%.

THERE IS NO BETTER, CHEAPER, QUICKER WAY, TO FEED COWS AND START CALVES

Quality Built

The first square bale EZ Ration Processor was built over a decade ago. The EZ Ration Processor’s patented ability to blend hays has literally saved the beef industry millions. Even though the EZ Ration Processor’s patented ability to blend feed puts it head and shoulders above the competition, we still continued to test, develop, and make improvements, to insure that our customers end up with the very best hay processor possible. The EZ Ration Processor has been producer proven from the ranch to the growing and backgrounding lots to the feedlots. It has been designed to give you years of trouble free service. If feedlots prefer it you know it is tough.

Daily Nutritional Requirements

Feeds & Nutrition

Copyright 1990

Daily Nutrient Requirements of Breeding Cattle

(All figures in U.S. pounds)

| Cow Weight | Daily Gain | Total Feed (as fed) |

TDN (energy) |

Protein |

| Dry pregnant mature cow – middle third of pregnancy | ||||

| 800 | 0 | 17.0 | 7.5 | 1.1 |

| 900 | 0 | 18.6 | 8.2 | 1.2 |

| 1000 | 0 | 20.1 | 8.8 | 1.3 |

| 1,100 | 0 | 21.7 | 9.5 | 1.4 |

| 1,200 | 0 | 23.1 | 10.1 | 1.4 |

| 1,300 | 0 | 24.4 | 10.8 | 1.5 |

| 1,400 | 0 | 25.9 | 11.4 | 1.6 |

| Dry pregnant mature cow – last third of pregnancy | ||||

| 800 | .9 | 18.7 | 9.2 | 1.4 |

| 900 | .9 | 20.2 | 9.8 | 1.5 |

| 1000 | .9 | 21.8 | 10.5 | 1.6 |

| 1,100 | .9 | 23.3 | 11.2 | 1.6 |

| 1,200 | .9 | 24.8 | 11.8 | 1.7 |

| 1,300 | .9 | 26.2 | 12.5 | 1.8 |

| 1,400 | .9 | 27.2 | 13.1 | 1.9 |

| Cows nursing calves-Avg. milking ability-1st 3 months post partum-10lbs milk / day | ||||

| 800 | 0 | 18.1 | 10.1 | 1.8 |

| 900 | 0 | 20.1 | 10.8 | 1.9 |

| 1000 | 0 | 22.4 | 11.5 | 2.0 |

| 1,100 | 0 | 24.0 | 12.1 | 2.0 |

| 1,200 | 0 | 25.6 | 12.8 | 2.1 |

| 1,300 | 0 | 27.0 | 13.4 | 2.2 |

| 1,400 | 0 | 28.4 | 14.0 | 2.3 |

| Cows nursing calves-Heavy milkers-1st 3 months pospartum- 0lbs milk / day | ||||

| 800 | 0 | 18.5 | 12.1 | 2.2 |

| 900 | 0 | 20.8 | 13.1 | 2.4 |

| 1000 | 0 | 22.9 | 13.8 | 2.5 |

| 1,100 | 0 | 24.8 | 14.5 | 2.6 |

| 1,200 | 0 | 26.4 | 15.2 | 2.7 |

| 1,300 | 0 | 28.1 | 15.9 | 2.8 |

| 1,400 | 0 | 29.7 | 16.5 | 2.9 |